The ‘Face’ of the Quilt: Fabric and Light Diffusion

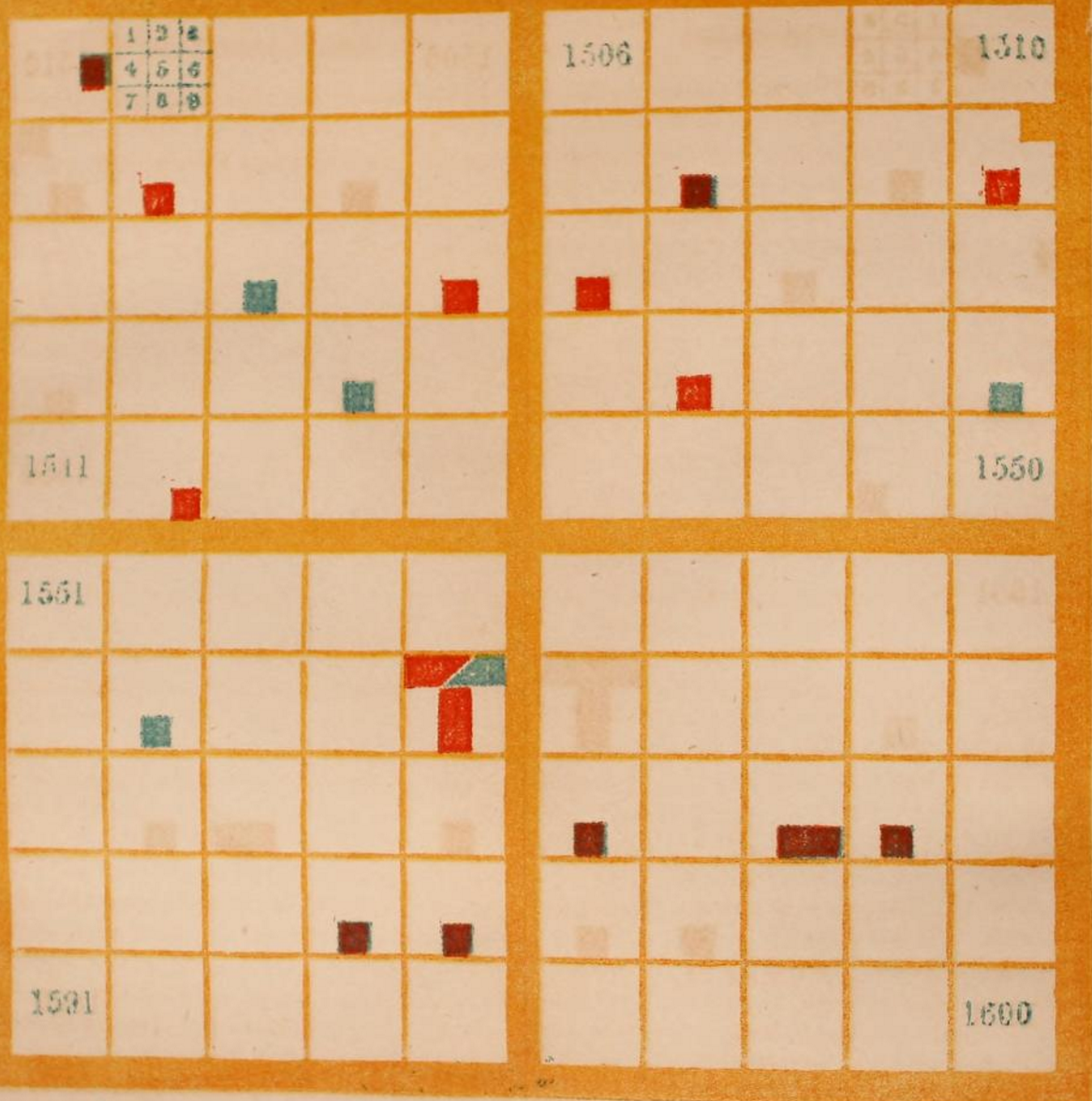

Per the admittedly true cliché, you never get a second chance to make a first impression. We are reimagining the original look and feel of the 1800s quilt in modern fabrics and designs. In taking this route, we need to ensure that the materials we select do not necessitate diverging from Peabody’s intellectual contribution and intent. To review, a rendering of the original design is as follows:

Aspects to consider include:

- How well do the NeoPixels perform in varying light conditions? Many example projects photograph NeoPixels in the dark. Most likely, we want users to interact with the quilt in partially dim lighting. If necessary, office lighting

- How will we diffuse the light to create defined borders and retain clarity? In Peabody’s work, richly colored square cutouts were placed on top of a grid. Now, we seek to recreate the effect using LED lights

- What kind of texture do we want, visually and physically? Should the two mismatch? As a result, how can it create convey a message? (i.e. a soft and smooth texture may convey innocence and warmth and a rough texture may convey stability, trustworthiness, weight)

- Do we want the hardware to be felt or obscured? Pragmatism may dictate this result, but the difference may determine whether the user perceives an electronic quilt or a different device

In regards to 1. Light conditions and 2. Hardware… We can examine projects made with NeoPixels from Adafruit. The company that created our LED strips publishes many popular example projects that illuminate (heh) the power of NeoPixels:

In regards to 2. Defined borders and clarity… we can take a cue from recessed LED light fixtures. Some office buildings opt for LED versus fluorescent lighting fixtures. In these cases, they may use panels of LEDs with polystyrene (PS) diffusing plates of varying thickness. A possible implementation could include a single 1 meter by 1 meter sheet of PS plastic with divisions cut between each touch location to allow for pressing. Examples of LED light fixtures include:

In regards to 3. texture… we have not decided between rough and smooth, but a possible implementation may include rough or smooth cotton fabric. Cotton is affordable, sturdy, and offers a wide range of textures. If choosing a rough fabric, it may be more difficult to find a color that is not a shade of light brown, light green, or in natural shades and block more light. Smooth fabrics tend to come in more modern colors and diffuse light more softly. Examples of fabric include:

In regards to 4. hardware salience… in meetings we have discussed how we might create the “LED sandwich.” A possible implementation is to create “troughs” for the LEDs by placing strips of foam in between each strip of LEDs. This way, the surface will feel roughly uniform, and a potential user may believe a single LED panel lies beneath. However, we may encounter issues with this approach because our neoprene is 1 millimeter thinner than our LED strips, as pictured:

Diagram depicting LED strips with our neoprene foam between; the strips are slightly taller than the foam we purchased

The Peabody Project’s present priority is to complete the physical product. We want to allow for interaction, say in a gallery or exhibition, and sooner than later allow anyone to learn and appreciate Elizabeth Peabody’s contributions to education and data visualization. Combinatorially we already see numerous implementations for our design, each with its own implications for the end product (financial cost, affective experience, etc.). After taking these ideas and experimenting on a small scale, we will be able to determine which path we will take for each.